Recent developments in decomposition and preservation of magnetic tape

Ian Gilmour and Viktor Fumic, National Film and Sound Archive, Canberra, Australia

Presented in the Technical Committee Open Session at the IASA/ASRA Conference, Canberra, 1992

Originally printed in the Phonographic Bulletin, issue 61 November 1992, pages 74-86.

ISSN 0253-004X

IASA members may download the PDF version at no cost. If you are not a member, why not join IASA?

Sound Archives typically rely on 1/4” analogue tape as a preservation medium, but many recent tape formulations have proven to have much shorter life spans than expected, with some failing much sooner than typical varieties from 30 or 40 years ago. Tape composition, mechanisms of decomposition, analysis and restoration are outlined, along with implications and strategies for preservation. Detailed discussion focuses on the success of acid and soluble content measurements, and low humidity rejuvenation of tapes with hydrolysed binders.

Table of contents

Introduction -Tape Construction

Apart from very early homogeneous types, most tapes consist of three primary components:

- the base

- magnetic particles or pigment

- binder.

The earliest commercial formulations used cellulose acetate as a support or base film as well as a binder for coated and homogeneous tapes. Poly(vinyl-chloride) or PVC has also been used since 1940 1, but both have been superseded in modern tapes by poly(ethylene-terephthalate) or PET, which has superior physical, hygroscopic and thermal properties. Under commonly encountered conditions of storage and use, it is one of the most chemically stable polymers available 2. Problems with physical deformation can occur through mis-handling or improper collection management, but with care these are normally of secondary concern.

Most modern tapes incorporate a back-coating of carbon particles to reduce static electricity which can discharge and attract dust. Pigmentation was first introduced in the late 1940s to distinguish the reverse side of the tape from the playing surface. From the 1950s as tape surfaces became smoother, matt back-coating was introduced to reduce air entrapment and to avoid slippage between layers or displacement of loose turns (ribbing or leafing) during spooling and in subsequent handling and storage.

Binders

Of the 3 main components in modern formulations, the binder system is considered to be the weakest. IASA's own literature over the last two decades has addressed a wide range of issues from print-through, stray magnetic fields and even detailed arguments about period playback equipment, without ever having focused on binders. Could it be that this is a purely antipodean issue? Recent industry articles in both the U.S.A. and the U.K. seem to suggest otherwise 3,4.

The binder probably has the toughest job of the three primary components. It has to perform several roles simultaneously:

Cohesion - it must hold the magnetic particles or back-coat together in a tough, wear-resistant layer of uniform dispersion, with each particle thoroughly coated, but without itself occupying excessive volume so as to reduce the density and therefore, signal carrying capacity of the tape;

Flexibility - to withstand successive bending and straightening from spooling/ unspooling and curving around the heads and guides of the tape transport.

Runability - it must allow the passage of tape through the transport with minimum friction and mechanical interference - flapping around, “stiction” or other irregularities which can cause flutter, modulation noise and related problems.

The two main families of binders in current use are polyester-urethanes (PE-U) and (PVC). Examples of PVC include drainpipes, shoe soles and LP records, which are believed to able to last for a century or more. PE-Us are used in such demanding applications as motor vehicle suspension bushes, casting or moulding of precision mechanical and electrical components, skateboard/roller-blade tyres and some of the toughest, most chemical resistant lacquers and finishes ever invented. Whilst neither is clearly superior, their success as tape binders depends on adherence to strict manufacturing tolerances, and on the exact composition, which can incorporate a host of additional ingredients such as lubricants, plasticisers, stabilisers, fungal inhibitors, anti-foaming agents, dispersants and the like.

Polyvinyl chloride

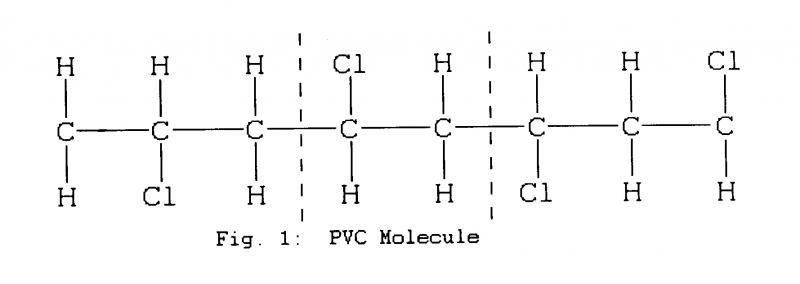

A slightly different form of PVC to that used in substrates is favoured by European manufacturers as a binder, despite a slight tendency to shed oxide even when new. (Fig.1)

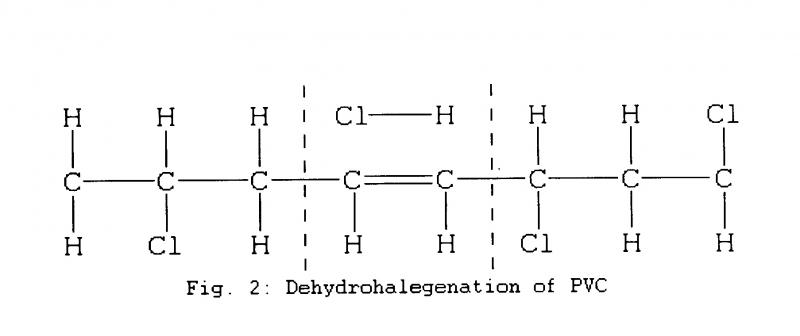

PVC typically breaks down by losing hydrogen and chlorine molecules which can produce hydrochloric acid (HC1) and leave double carbon bonds. (Fig.2)

Unlike the relatively rigid vinyl discs which incorporate a proportionally far smaller load of pigment as well as stabilisers to prevent decomposition, tapes typically incorporate 40% or more by volume of magnetic particles or pigment along with the binders themselves.

Polyester-urethanes

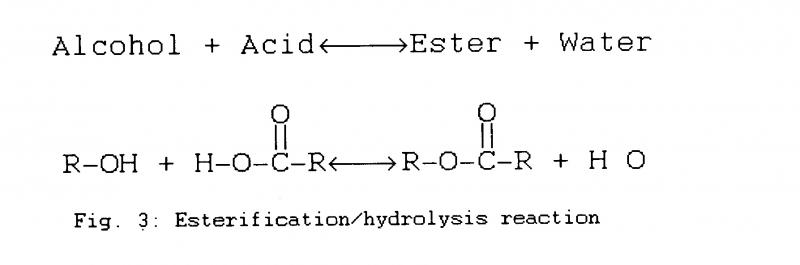

Polyesters are formed by reacting carboxylic acid and an alcohol to produce esters and water. This esterification reaction is reversible by a process of hydrolysis, in which water and esters are consumed, whilst acid and alcohol are produced (Fig.3). Being a reversible reaction, it is an equilibrium equation; in the presence of a certain moisture concentration, i.e. airborne humidity. polyesters will evolve or consume water from the surroundings until an equilibrium is reached.

The PE-U in tape binders are typically cross-linked co-polymers. The chains are arranged in lattice-shaped structures joined by ester linkages. These aliphatic esters which number roughly 5 or 10 times as many as the polyurethanes are much more prone to hydrolyse than the PET substrate 5.

Measurement of Decomposition

Two main approaches are of interest to archivists:

- Physical means, such as optical characteristics, viscometry, cohesion/shedding, adhesion, buildup of sticky residue of heads and guides;

- Chemical analysis, inc chromatography, infra-red or mass spectra, nuclear magnetic resonance (NMR), solvent extraction, and pH determination.

The main drawback with relying on visible indications of decomposition or physical symptoms evident during playback or spooling, is that they often don’t show up until it is too late - once binder failure has occurred. Despite this fact, it is still too often the primary or only means of detecting binder decomposition. Indeed, manufacturers still advise clients that this is the simplest and most reliable means of determining the state of tape collections 6. Certainly it is the ability of magnetic tapes to retain their physical integrity for running on a tape transport to reproduce a faithful signal which is of ultimate concern.

Chemical condition and quantitative measurement of binder condition are of more than just academic interest, however; they serve as an early warning of problems which axe building up, and allow time for planning and implementing the task of treating and dubbing original or historical tapes, particularly when work on large collections must be prioritised. In conjunction with accelerated aging, stability testing is an important means of selecting formulations for recording and acquiring new material, as well as dubbing the sonic content of older, unstable carriers.

Of all the available options, solvent extraction (SE) and pH are of particular interest, and have been used in recent years at the NFSA. Spectral analysis and chromatography are powerful tools for those fortunate enough to have the facility, although results often need careful interpretation. They can be useful for initially testing new or unknown formulations to help in analysing the different constituents. Binders in the 1970s have failed prematurely due to the inclusion of low - as well as high- molecular weight polymers, despite an apparently acceptable average molecular weight. Manufacturers have cited more accurate analysis of the spectrum of molecular weights in quality control of raw materials as a means of improving stability of binder formulations 7,8. SE and pH measurement can be routinely implemented more readily with simpler equipment and less skilled personnel, provided that they are adequately trained.

Solvent Extraction

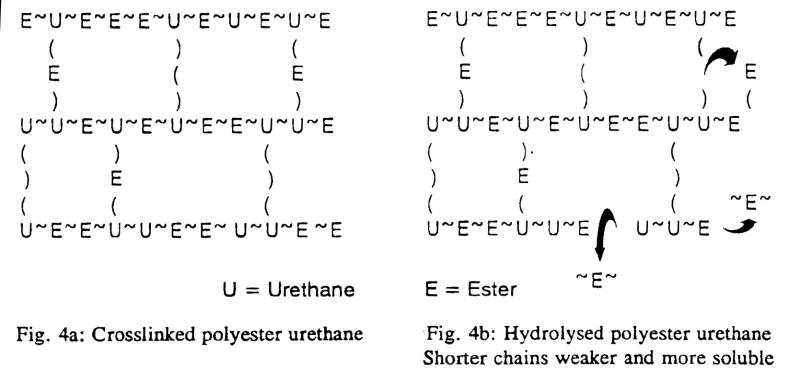

As PE-U binders degrade, scission of ester linkages occurs by hydrolysis, the polymer chains become shorter and the binder is said to lose molecular weight. A characteristic of such lower molecular weight polymers are that they become gummy or sticky rather than retaining their strength and integrity as an elastomer. Whereas the properly cross-linked binders are largely insoluble, the lower molecular weight residue will literally wash away in solvents such as acetone and methyl ethyl keytone (MEK) (Fig.4). A technique put forward by Cuddihy 9 in 1980 was to weigh a sample of tape before soaking in solvent and dissolving out the low molecular weight binder residue, then re-weighing the sample to determine by difference (percentage w/w) the amount of broken down residue lost in the process of extraction.

Since a PE-U tape in good condition has only a small percentage of solvent-extractable residue, typically 0.5-1%, whilst sticky unplayable tapes are often closer to 4 or 5%, it is possible to obtain a rough indication of binder condition even without a reference level for a particular formulation. Similarly an artificially aged tape showing an increase of more than a few percent extractables is inclined to instability, particularly when one accounts for the nature of additives such as plasticisers and fatty-acid lubricants. If a collection of tapes is properly monitored, with periodic measurements taken and records kept (along with control samples) from when new or prerecorded tapes first enter the Archive, a pattern of understanding may be developed which can serve as a basis for treating and dubbing material before it reaches a critical state. With experience, SE then can be correlated to playability for tapes of a given age and formulation.

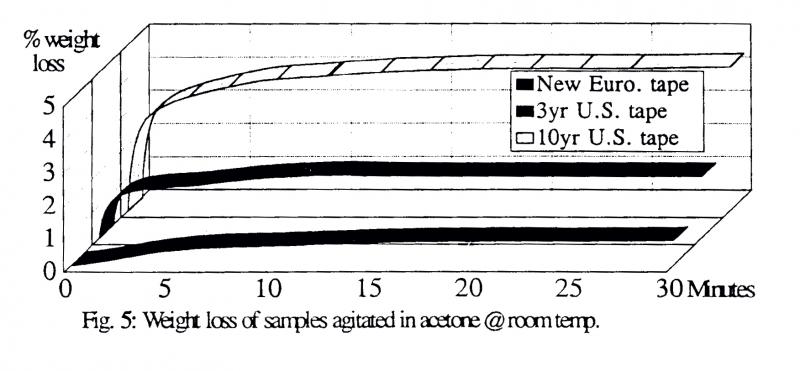

Our own test method consists of weighing then immersing 50-100mm long samples in glass vials containing 20-50ml HPLC-grade acetone. After removal from the solvent and drying in air, the final weight is used to calculate percentage weight loss. Initial readings over logarithmic time intervals indicated that 20-30 minute immersion followed by 1-5 minutes drying time was sufficient to give stable, repeatable measurements (Fig.5).

Care and skill is required for solvent extractions on fragile tapes including those with PVC binders, which lose oxide and/or backcoat in the process. Techniques for filtration and evaporation can be used to avoid the apparent variation which has confused some attempts at such analysis. A team at the U.S. National Bureau of Standards produced similarly variable results by using tetrahydra furan (THF) which dissolves stable, high molecular weight polymers rather than acetone-soluble residue alone 5.

pH Determination

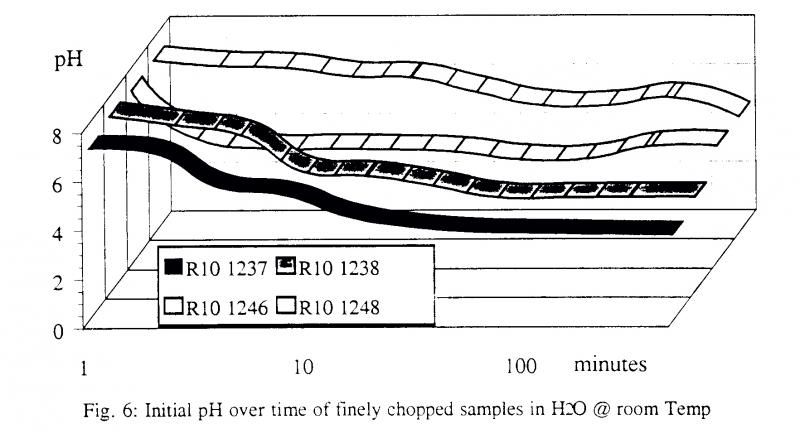

An alternative process is used to complement and verify results of solvent extractions and provide added indications of PVC binder condition. As previously explained, dehydrohalogenation of PVC produces HC1, whilst hydrolysis of PE-U produces carboxylic acids. Acids are normally measured on an inverse logarithmic scale of H+ ion concentration simply called pH. A technique commonly used for testing film supports 10 involves soaking finely chopped tape samples in distilled H20, then measuring pH. In our initial trials we arrived at H20:tape ratio of 10:1 w/w, over an immersion time of 2 hours with constant agitation (Fig. 6).

Accelerated Aging

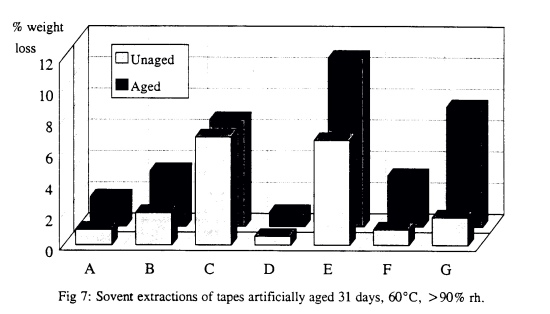

Most archives will be involved in recording and/or dubbing older unstable material onto newer, more stable media to preserve the sonic content. It is important to determine at least the relative stability of the formulations available so as to optimise the chances of dubbed material surviving. In order to ascertain the applicability of these methods of analysis for assessment of stability, we regularly study performance of current mastering tapes exposed to high humidity. Whilst a range of conditions are used in accelerated aging, including cycling between low and high humidities and temperatures, we were particularly interested in how tapes performed at high temperature and humidity, and whether this would increase the rate of chemical decomposition. In a recent test over 31 days at 60°C and 90% relative humidity (R.H.), seven popular tapes all showed a greater tendency to shed and an increase in SE [fig 7].

In order to provide repeatable measurements of shedding or binder cohesion, a test jig has been built which rubs a sample of tape held at 500g tension on a 1cm cylindrical swab rotating at 300rpm. The swab is wetted by isopropanol and slowly fed across the tape to avoid clogging. The time to rub completely through the oxide layer is noted. The processes of accelerated aging and analysis by these methods are believed to approximate, rather than completely model actual tape behaviour, although the high degree of repeatability and strong correlation between test results and actual performance has been found to provide a good basis for comparison of different formulations.

Conditions for Storage and Treatment

Given the destructive role of airborne moisture in the decomposition of polymers used in magnetic tapes, the theoretical possibility of reversing the reaction, and the need to recover information from degraded tapes, investigations were conducted into low humidity rejuvenation. The first goal was to at least restore tapes to a playable condition so that they could be dubbed. The increasingly popular industry practice of baking tapes at up to 60°C was included in our study. An absolute ceiling is indicated by the glass transition temperature (Tg) for PET of around 70°C. It is quite possible that changes in crystallinity or chain mobility may occur at even moderately elevated temperatures, hence it is advisable to use caution when treating tapes in this manner.

Initial trials were conducted on expendable tape samples of various ages up to 12 years, some of which were already showing signs of hydrolysis - squealing, shedding gummy deposits, and SE of 4-5%. Musical and spoken-word programs and test tones were used to measure side effects such as print-through and scrape-flutter. Whilst some tapes recovered to a playable condition after 24 hours at 55°C and ambient humidity (air at 50% RH at 22°C drops to less than 10% RH when heated to 55°C), the recovery only lasted for a few weeks or months and side effects such as print-through and packing damage occurred.

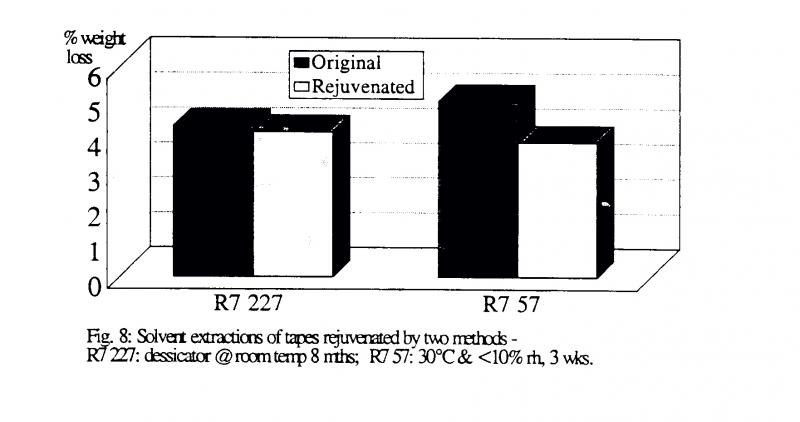

In order to try a more cautious method, a squeaky, shedding 7” original tape from the collection with SE of 4.3% was placed in a partially evacuated glass desiccator charged with barium oxide over a period of 8 months at room temperature (22°C ). The tape recovered from a state of squealing after a few minutes of playback with moderate shedding, to a point of playing from end to end (30 minutes) with no squeal and very slight shedding. The SE fell to 3.9%. At around the same time, a series of tapes in varying condition was treated for 3 weeks at 30°C and <10% RH. Most of the tapes recovered to a degree, although for some the improvement was slight rather than dramatic. We realised that patience and greater understanding would be needed to pursue the process further. A typical tape from this batch is shown in Fig.8, along with the earlier example.

Arrhenius equations can be used to help estimate time elapsed before failure or recovery in such reactions. A simplified model can be expressed as:

In LE = k/T

where LE equals life expectancy or time elapsed before failure/recovery, T equals temperature, and k is a rate constant based on the activation energy for a particular formulation, and the humidity of the storage or treatment environment. Rate constants from such projections suggested that longer times or higher temperatures were needed to restore many tapes to a more playable condition.

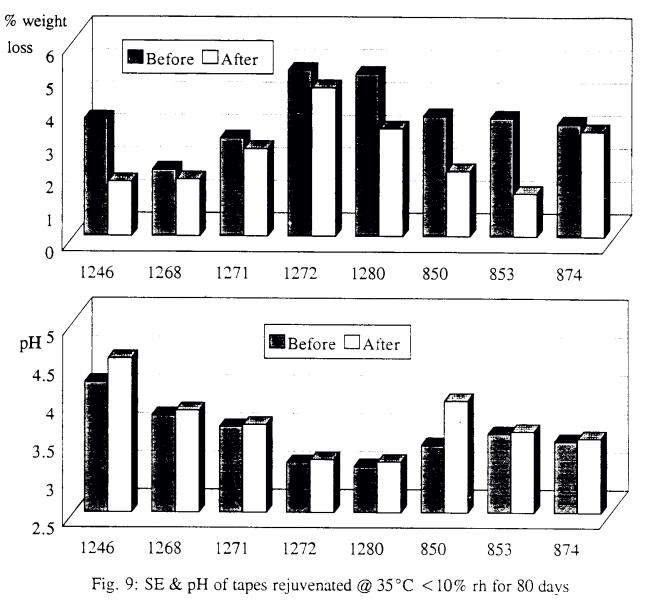

Our current program is based on a limited range of temperatures (usually around 35°C) with longer treatment times and very low RH (below 5%) regulated by means of chemical desiccant and/or thermo-mechanical (refrigerant) systems. Stable laboratory-type environmental and vacuum chambers are used to avoid pack stress or damage from fluctuating temperatures which typically occur in domestic ovens. Tapes treated in this manner show consistent improvement in key parameters. Fig.9 shows the results of SE and pH of representative samples from recently restored collections; the sequential shelf numbers appear along the x-axis. Significant recovery of most tapes took place over 6-10 weeks with further improvement after this time. Although some forward planning is necessary to organise workflow between the lab and studios to maintain rates of subsequent dubbing, the actual labour component for batch treatment and monitoring is not great.

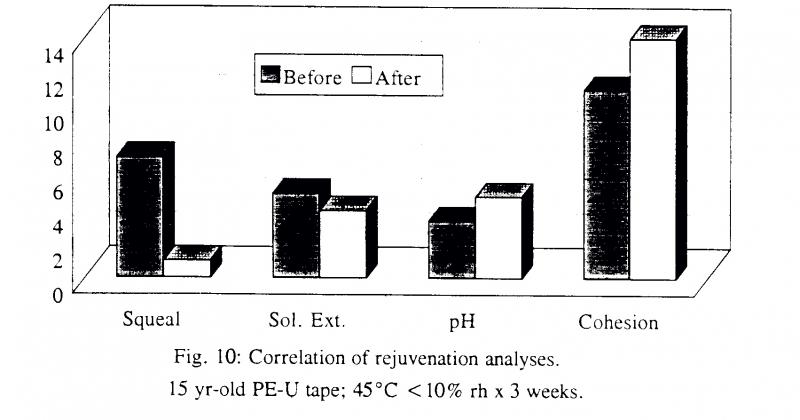

If tapes are needed in a hurry, a higher temperatures may be used, but we stop well short of ‘baking' tapes as is commonly advocated. At temperatures over 35°C tapes are normally interleaved with blank stock, separating layers to minimise print-through. Typical results for a fast-tracked tape are shown in Fig.10 which illustrates the correlation between key measurement parameters and playability. As well as SE and pH the graph shows the improvement in cohesion as previously described, and audibly-assessed squeal falling from 7 (pronounced after a few minute's playback) to 1 (barely discernible). Specialised cleaning and reproduction machinery may still be used on many tapes to ensure that faithful dubs are made.

It is understood that complete reversibility of decomposition may be limited by factors such as the migration of plasticisers, lubricants and other constituents including broken- down products of decomposition; secondary reactions, crosslinking or combinations of constituents forming different compounds to those originally present; changes in physical properties of tape over time.

Summary

In modern ferric oxide tapes on PET substrates, the PE-U and PVC binders are likely to be the least stable component. Hydrolysis is indicated as a significant factor in the failure of PEU whilst dehydrohalogenation can pose a threat to PVCs. Moisture (airborne humidity), temperature and acidity are all contributing factors.

When properly conducted, solvent extractions and pH measurements provide a useful indication of relative binder condition and show a strong correlation with other physical characteristics.

Accelerated ageing can show up relative stability amongst similar formulations and should be used systematically by archives on new stocks for recording and dubbing. Further studies of tapes aged and treated under conditions closer to ‘real life* are needed to derive more accurate rate constants for the forward and reverse equations.

The complexities of tape composition, and the interaction between tape condition, playback environment and machinery make it difficult to exactly predict future behaviour of media, although basic housekeeping rules must still be followed. Storage at low humidity and temperature (less than 35% RH and 18°C) is indicated, although both are hard to maintain simultaneously. Because the effects of prolonged storage or treatment at very low humidities (less than 20%) are not completely understood (possible loss of lubricant, plasticiser migration, etc.), common sense would indicate a balance of low humidity and temperature; the rate of most reactions such as hydrolysis is slowed at low temperature.

Despite a modicum of success with low humidity rejuvenation, prevention is still better than cure. We cannot be sure of total reversibility of the decomposition process or a complete recoverability of playability for all formulations. The long-term costs of low humidity storage are certainly less than for treatment and dubbing of hydrolysed tapes. Indeed, low-humidity storage and treatment are part of a continuum of environmental conditions; having stored our tape under conditions which stabilise or even reverse hydrolysis, they can be played immediately after retrieval rather than having to wait even 24 hours for baking! Packaging with desiccants to provide a dry micro-climate, or hermetic sealing may be appropriate in some cases (PE-U can consume moisture from a finite micro-environment as it hydrolyses until an equilibrium is reached). Further investigations are needed, however.

References

1. Engel, F.K. ‘Magnetic Tape From the Early Days to the Present' Journal of the Audio Engineering Society 36:7/8 July/August 1988.

2. Carison, D. J. & Milnera, S.M. ‘Hydrolysis of Resin-Coated Poly(ethylene Terephthalate) Yarns' Journal of Applied Polymer Science 27 (1982).

3. Fox, B. ‘Tape Life - An Era of Concern' Studio Sound, December 1990.

4. Stosich, M. N. ‘Archival Revival' Audio, November 1990

5. Brown, D.W., Lowry, R. E., & Smith, L.E. ‘Prediction of the Long Term Stability of Polyester-Based Recording Media' NBSJR 82-2530 June 1982.

6. Meuller, R. Communication through BASF Australia, April 1991.

7. Curtis, J., ‘Environmental Aging of Magnetic Tapes' Ampex Corporation, Applied Technology Development: February 1988.

8. Layne, F., Ampex Corporation. ‘Seminar on Tape Stability and Preservation' NFSA Canberra: August 1991.

9. Cuddihy, E. ‘Kinetics of the Humid Aging of Magnetic Recording Tape' IEEE Trans. On Magnetics 18:5 September 1982.

10. Ram, T. ‘Tutorial on the Conservation of Motion Picture Film' NFSA, Canberra: January 1992.