3 Passive Preservation: Environmental Factors, Handling and Storage

Water/humidity (section 3.1)

Temperature (section 3.2)

Climatic storage conditions (section 3.3)

Mechanical deformation (section 3.4)

Dust, foreign matter, (air) pollution (section 3.5)

Light, ultraviolet radiation, x-rays (section 3.6)

Stray magnetic fields (section 3.7)

Each section covers the various carriers: mechanical, magnetic, optical, and solid state.

3.1 Water/humidity

Water is the greatest natural enemy for all audiovisual carriers. It has direct chemical and indirect influences on the stability of carriers. Direct chemical influences are hydrolysis and oxidation of several carrier components as well as dissolution of some carrier materials.

3.1.1 Hydrolysis is a chemical reaction involving water, omnipresent in form of humidity in the air, as the central agent. Some polymers are prone to hydrolysis. Acids and metal ions act as catalysts in supporting such processes. The reaction changes the chemical and the physical properties of the original polymer, often producing a by-product that acts as an auto-catalyst that enhances the destructive process. Some hydrolytic processes are (partly) reversible; others are not.

3.1.1.1 Vinegar syndrome. A widely known hydrolytic polymer breakdown is the so-called vinegar syndrome. This process that deteriorates cellulose acetate (CA) films beyond retrievability, was first observed in the late 1940s. It has, however, been more widely experienced since the 1980s, particularly in tropical film archives. Acetic acid is one of the products of the process of hydrolysis of CA and acts as an auto-catalyst to accelerate the chemical reaction. Because of its smell it has become known as vinegar syndrome. With the advancement of the process, affected films lose their structure and become unplayable.

Magnetic film sound carriers with a base of CA are particularly at risk because of the catalytic properties of metal in the form of the iron oxide used as the magnetic pigment. Cellulose acetate audio tapes are also affected, but not, however, to the same disastrous degree as films because of their sub-critical mass. Apart from smell, acid detection strips assist to objectively assess the process. CA hydrolysis is not reversible.

3.1.1.2 Pigment binder degradation. Some binders of modern magnetic tapes (2.2.1.1.2) are also prone to hydrolysis causing the tapes to become sticky. Because the symptoms of this kind of hydrolysis are reversible to some degree, such tapes can generally be reconditioned for replay by exposing them to low humidity and elevated temperatures or a combination thereof. For details see IASA-TC04, 5.4.3.3. Recent research has, however, revealed that hydrolysis of binder is only one of several reasons for the so-called sticky shed syndrome (2.2.1.1.2).

3.1.2 Direct contact with water. Direct short contact with water is only dangerous for some kinds of instantaneous discs such as those made from gelatine, cardboard etc, and for hard disk drives. For other carriers water is not immediately dangerous, as long as the contact is short, the carriers are carefully cleaned if the water was dirty, and the carriers are thoroughly dried soon after coming into contact with the water. In fact, cleaning with de-ionised water is a recommended step in preparing vinyl and shellac discs for replay using a professional disc-cleaning machine (IASA-TC 04, 5.2.3, 5.3.3).

The major problem with carriers exposed to water influx is the logistical challenge of cleaning and drying the contaminated carriers, particularly for magnetic tape cassettes. Another logistic problem is the separation of carriers from paper and carton materials, such as LP albums, and the drying of those, before they become affected by mould. If greater quantities are affected, vacuum freeze drying, successfully developed for the rescue of paper and book materials, may be the only chance to safeguard paper and carton materials accompanying audiovisual material. The applicability on audiovisual carriers themselves and specifically on magnetic tape, has, as yet, not been sufficiently investigated (for influx prevention see 4.2).

3.1.3 Oxidation is another chemical reaction triggered by water. It is a potential threat to non-oxidic, pure metal particle magnetic pigments as used for compact cassettes type IEC IV, for R-DAT and for most digital video formats (2.2.1.1.1.2). Oxidation also affects the reflective layers of optical discs, except for those made of gold.

3.1.4 Dimensional influences. Humidity has also an influence on the dimensions of materials used as components of audiovisual carriers. For CA tapes, the humidity related expansion coefficient is quoted to be 15 times higher than that for polyester based tapes.16 A considerable dimension change must also be taken into account for several materials used for instantaneous discs, such as cardboard, gelatine, or the information carrying lacquer.

3.1.5 Indirect influence through bio-degradation. Water causes bio-degradation, specifically mould (fungus growth), which happens at prolonged exposure to relative humidities (RH) of 70% and higher. Fungi of various kinds are present everywhere in the world and affect nearly all audiovisual carriers. Fungi “eat” the surface of analogue mechanical carriers, which leads to excessive surface noise—a particular problem with wax cylinders. Fungi grow on magnetic tape pigment layers, which renders replay difficult or impossible. Fungi are also known to affect CDs, rendering them unplayable. Chemical prevention of fungus must be seen as a last resort. Unfavourable chemical interactions, particularly with the variety of magnetic pigment binder formulations that exist, can never be excluded. Chemical treatment may also endanger the health of archive staff.

Because of its potential for unfavourably influencing carriers, both directly and indirectly, fungus growth must be prevented by keeping relative humidity low. Any direct contact with water, even when permissible in principle, must be kept as short as possible.

3.1.6 Humidity/temperature interrelation. It must be noted that relative humidity and temperature are interrelated (for more details see 3.2.3).

3.2 Temperature

3.2.1 Physical influences.

3.2.1.1 Dimensional influences. Temperature influences the size of materials: generally, carriers expand with rising and shrink with falling temperatures. This is also true for tapes. Polyester tapes have the lowest thermal expansion coefficient, while that of CA is quoted to be three times higher.

With CA and PVC tapes, this leads to looser tape packs if temperatures rise and to tighter packs with lower temperatures. With PET base films, however, there is one anomaly: these are pre-tensilised which causes their thermal expansion coefficients to be significantly higher in the dimension of thickness than of length. Thus, wound-up PET tapes “swell” with rising temperatures — each layer of tape becomes thicker — which is not compensated by elongation. This increases the tension within the tape pack. Conversely, PET tapes become 16 FIAF 1986, 11.1.1.2. looser with falling temperatures. This calls for different relaxation measures for CA and PVC tapes to those for PET tapes when changing climatic storage conditions (3.2.4).

Dimensional changes are particularly dangerous for lacquer discs. Because of the different thermal expansion coefficients of the metal or glass substrate and the brittle lacquer coating, a temperature change may trigger the cracking of the latter.

Because of these disadvantages and potential threats, specifically for tape materials and lacquer discs, the stability of temperature is of greater importance than the chosen absolute value (see 3.3).

3.2.1.2 Irreversible influences on polymers. For some polymers used as components of audiovisual carriers, elevated temperatures have an irreversible influence. If heated beyond certain temperatures, their properties are changed and are not restored after lowering the temperature again. Temperature thresholds differ widely for various materials, but it can be stated that temperatures up to 35°C do not cause any immediate irreversible effects or lead to any deterioration of any current audiovisual carrier.

3.2.1.3 Thermoplastic materials. This group of polymers softens at higher temperatures. These polymers are used for the production of containers, cassette shells, etc. The inadvertent exposure of such materials to elevated temperature, even to sunlight, may lead to an irreversible deformation. This is also a specific threat to vinyl discs.

3.2.1.4 Print-through. Temperature influences print-through on magnetic tape: the rise of print through versus time is steeper with higher, and flatter with lower temperatures (see 3.7.2.5).

3.2.1.5 Curie point. Magnetic stability (coercivity) depends on temperature. At and beyond the Curie point, magnetic stability is lost. The lowest Curie point of widely used magnetic pigment is 128°C for CrO2, while the point for iron and iron oxide is above 300°C. This phenomenon, however, is positively employed in magneto-optical recording (2.3.1.4).

3.2.1.6 Temperature range. In order to extend life expectancy, photographic materials are often stored at temperatures below the freezing point. For magnetic tape, cold storage is discouraged because some, not all, lubricants exudate at a temperature below 8°C (2.2.1.1.1.4). At the higher end, 35°C should not be exceeded (3.2.1.2). Within this range, temperature only affects the physical dimensions of carriers and the speed of chemical processes.

3.2.2 Indirect chemical influence. Temperature determines the speed of chemical processes and, therefore, ageing or deterioration. Subject to the limits set out in 3.2.1.6, it can be stated as a rule of thumb that the speed of chemical processes is doubled by an increase of 10°C, or, on the other hand, the speed of ageing is slowed by 50% by lowering temperature by 10°C — a doubling of life expectancy.

3.2.3 Humidity and temperature interrelation. Temperature determines the absolute amount of water air can hold in gaseous form (vapour). Higher temperatures hold higher amounts of vapour, while lower temperatures hold less. If a given room is cooled without simultaneously dehumidifying the air, the relative humidity rises until 100% RH is reached. At this temperature, called the dew point, superfluous vapour condenses in the form of water on the coldest surfaces (see figure 30). Any air conditioning must, therefore, control both parameters simultaneously (see 4.3). Most conventional air conditioning equipment does not dehumidify sufficiently, thereby inadvertently raising relative humidity and increasing the threat to carriers, counter-acting the benefits of the lowered temperature

3.2.4 Temperature/humidity changes, as already mentioned in 3.2.1.1 above, can be more dangerous to carriers than stable, but sub-optimal, absolute values. Changes in temperature, but also in humidity, cause dimension changes, resulting in unnecessary stress to carriers. At highest risk are discs composed of different materials, e.g. lacquer discs, but magnetic tapes are also affected, specifically high density helical scan formats. The other basic danger is the possibility of condensation when bringing cold carriers into a warm environment.

Consequently, permanent storage conditions should be designed to have minimal temperature and humidity changes. During transportation, carriers must be protected by adequate logistics and containers (see 4.8). Changes of climatic parameters of longer duration require acclimatisation (staging) periods. For all materials, except lacquer discs, the temperature gradient should not exceed 3°C and the relative humidity gradient 5 percent points over a period of 24 hours. Additionally, to compensate for the different tensions within tape winds due to temperature changes (3.2.1.1), tapes must be relaxed by re-winding when bringing CA and PVC tapes to cooler storage conditions and PET and PEN tapes to warmer storage conditions. Lacquer discs, because of the threat of crackling due to different expansion coefficients between coating and substrate, are threatened by moves in both directions. Such transports should, therefore, be kept to the absolute minimum and be accompanied by long acclimatisation (staging) periods over several days.

The danger of condensation when bringing cold carriers into warmer areas must not be underestimated. Sufficient airing must be allowed until the carrier temperature is equalised.

3.3 Conclusions for the choice of climatic storage conditions

Conclusions for the choice of climatic storage conditions. On the basis of the above discussion, it becomes clear that the choice of storage conditions is mainly determined by two conflicting principles: to keep humidity and temperature low (to retard chemical deterioration), and to avoid climatic changes (to prevent condensation and to minimise mechanical stress, most importantly for tapes and lacquer discs).

The minimum/maximum values to be kept to are:

| Humidity | Absolute maximum for prolonged exposure | 60% RH |

| Minimum | 25% RH | |

| Temperature | Absolute maximum | 35°C |

| Minimum | 8°C for magnetic tapes |

As explained, the precise values between these maxima/minima, have no immediate negative or positive influence. However, in the mid- and long-term they determine the life expectancy of carriers. Of higher importance, however, is the stability of the chosen climatic conditions (3.2.1.1, 3.2.3, and 3.2.4).

For the purpose of storage recommendations, the following definitions are made:

| Humidity (ranges) | Medium | 40-50% RH |

| Low | 25-35% RH | |

| Variability1 | narrow ± 3%RH relaxed ± 5%RH |

|

| Temperature (mean values) |

Room2 | ~20°C |

| Cool | between 8 and12°C | |

| Variability3 | narrow ± 1°C relaxed ± 3°C |

1 Permissible variations around the mean values are low frequency (annual) deviations.

2 This mean value of “room temperature” condition reflects the situation in moderate climatic zones and is not necessarily obligatory for tropical countries. There, it may be prudent to choose a higher mean temperature, e.g. 25°C, and invest the saving in energy costs in effective dehumidification instead. This will also improve the well being of archival staff members, who generally may not find first-world climatic working conditions acceptable.

3 Permissible variations are low frequency (annual) deviations.

Please note: Temperature/humidity ranges and variability must not be added. The chosen mean value should be kept to the permissible variability.

Recommended storage conditions

| Collections | Humidity | Var | Temp | Var |

|---|---|---|---|---|

| Access storage Tape collections in frequent use Mechanical and optical carriers (except lacquer discs) |

low

medium |

narrow

relaxed |

room

room |

narrow

relaxed |

| Preservation storage Tape collections Mechanical and optical carriers (except lacquer discs) |

low

medium to low |

narrow

relaxed |

cool

room to cool |

narrow

relaxed |

| Access and preservation storage Lacquer discs |

medium | narrow | room | narrow |

The climatic conditions of studios and laboratories should be the same as, or very close to storage conditions. Whenever possible, work with carriers (e.g. routine inspection) stored at cool and low humidity conditions, should be carried out on the spot; otherwise, carriers must be adequately acclimatised.

The choice of target values for humidity and temperature is always a compromise between accessibility, comfort, and the health of operators on the one hand, and costs on the other. It must be further noted that even the lowest affordable values do not prevent, but only retard deterioration. Therefore, archives should choose those parameters that they can afford to keep 24 hours a day all year round. Within the permissible ranges, stability is more important than the absolute values of temperature and humidity.

3.4 Mechanical deformation

Mechanical deformation is a major threat, which affects all kinds of audiovisual carriers.

3.4.1 Mechanical carriers

Fragile carriers (cylinders, shellac discs) must be given special attention when handled and transported. Extreme care should be given when mounting of cylinders on replay machines equipped with mandrels. Invisible cracks may lead to the bursting of such cylinders when mounted with too high a pressure. Additionally, keeping cylinders in mobile shelves is inadvisable. Best transport protection is achieved by tight packing within shock absorbing containers.

All mechanical carriers are prone to surface damages, which will cause audible artefacts (clicks, crackle, etc.). Additionally, the information carried by the grooves is specifically threatened by maladjusted mechanical pick-up systems and wrongly chosen styli. Both may cause considerable damage (IASA-TC 04, 5.2 and 5.3).

Because of the susceptibility of all mechanical carriers to physical damage, their handling requires staff with manual skills and special training.

3.4.2 Magnetic carriers

3.4.2.1 Magnetic tape. Mechanical integrity is a commonly underrated factor in magnetic tape preservation. In order to minimise stress, particularly with brittle CA tapes and all kinds of thin tape, tape handling must be optimised by using the latest generation of replay equipment that permits lower tape tension while still providing intimate tape-to-head contact. Such equipment will also allow fast winding at relatively slow speeds (“library wind”).

Most importantly, all open reel and cassette tapes must be stored with absolute flat winding packs only, as any stepped wind will create curled tape edges. Generally, one of the two tape edges is the reference in guiding the tape through the machine, especially with rotary head formats. Any malformed edges will result in vertical tape movement causing a variety of replay artefacts such as oscillation of stereo balance in audio or “flicker” through tracking problems in video recordings. Flat winds can best be achieved by winding the tape forward after use to its end and then back over its entire length in one continuous pass at library wind speed. Machines generally failing to achieve flat winds must be serviced or exchanged. Some tapes, however, may resist the production of a flat wind even with the use of a library wind option. In these cases, the tape should be played at a high replay speed to achieve a flat wind for storage.

Figure 21: Tape rewound before its end. The step left in the wind will cause a deformation in this area. For flat tape winds, tapes and cassettes have to be rewound over their entire length.

Figure 22: Uneven tape wind causing tape edge deformation.

Figure 23: “Windowing“. Manual intervention may be needed to get a flat wind without damaging the tape through friction by slipping tape.

Flanges of plastic and metal reels must be absolutely flat to avoid touching the tape during replay and specifically in the fast wind mode. Additionally, tape guides must be adjusted to ensure tape packs are formed in the middle of hubs, avoiding squeezing tape towards one of the flanges. Slots in the hubs to take up leader tapes have often led to a permanent deformation of several winds of tapes after many years of storage. Misshapen reels must be replaced, preferably by ones with slot-less hubs. Permanent slot marks can also be removed by a slightly different placement of the leader tape into the slot. Regular repositioning, however, would be needed to avoid new deformations.

The use of flangeless hubs originated with the original German “Magnetophon” of the 1930s and was maintained for studio and radio applications in continental and Eastern Europe thereafter. Its application requires back-matted tapes, machines with adequate tape tension control in all operating modes, and, above all, careful and skilled handling. Such freely wound tapes are stored on their hubs, hanging on a suitable suspension in the centre of the box. It may happen, however, that the tape pack falls apart, due to pressure on the hub, or a loose wind (see figure 11). Restoration of the tape wind calls for manual skill and patience. Special devices, known as “Wickelretter”, which have hinged, sectional hubs that can be moved inwards to fit inside the pack and then moved outwards again to hold the tape pack while slowly rewinding the tape on to a new spool.

Figure 24: “Wickelretter” - device to assist the rescue of tape packs if hubs had slipped out.

Once CA tapes become brittle, they often have a tendency to “escape” from a flat pack during fast wind. It is, therefore, a wise precaution to wind them onto spools.

With cassette tapes, the loading and unloading procedure constitutes a significant stress to the tape resulting in measurable drops-outs after several tens of such actions. Also, malfunctioning mechanisms may jam and damage, if not destroy, the tape. Consequently, cassettes must only be loaded and unloaded at the unrecorded portions at the beginning or at the end of tape. If this is done, tapes that get jammed can be repaired by cutting off the damaged part without loss of recorded material. Therefore, when recording a programme on a cassette, sufficient room should be left blank as a loading area at the beginning and the end.

Regular cleaning of tape guides and heads—at least daily—must be performed using tools soft enough to avoid damage to heads and guides. Such damage will scratch tape surfaces, which endangers its chemical stability (2.2.1.1.3).

3.4.2.2 Hard disk drives. Generally, because of their moving parts, hard disk drives should not be exposed to mechanical shocks. Moreover, it must be noted that shock damage is more likely under operating than in non-operating conditions, when the read head is safely parked away from the hard disc surface. Hard disk recorders must always be handled with great care, particularly during recording and play back.

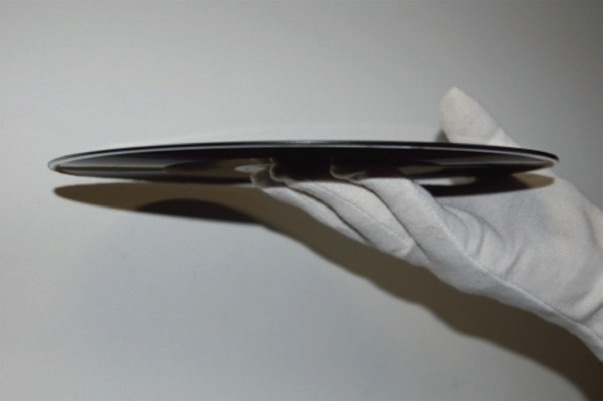

3.4.3 Optical discs

Optical discs must be kept free of mechanical damage and scratches. Scratches on the read-out surface will obstruct and/or divert the laser beam, while a damaged protective layer on CDs and BDs will endanger the chemical integrity of the reflective layer. Writing on protective layers (label side) can only be done on recordable discs and then only by using special CD felt pens. Ordinary felt pens must not be used as their solvents may dissolve the protective lacquer. Writing with hard tipped pencils or ballpoint writers may mechanically disturb retrievability. Bending of optical discs must be avoided, as this may crack the reflective layer. Consequently, when releasing optical discs from the centre holding clamp, two hands should be used — one to release the holding mechanism and the other to remove the disc.

3.4.4 Solid state carriers

Daily experience with solid-state data carriers suggests a level of robustness against some shocks, e.g. when dropped on the floor. It should be borne in mind, however, that due to their microscopic structure, some mechanical stresses, e.g. bending memory sticks in pockets, may lead to their immediate destruction.

3.5 Dust, foreign matter, (air) pollution, pests

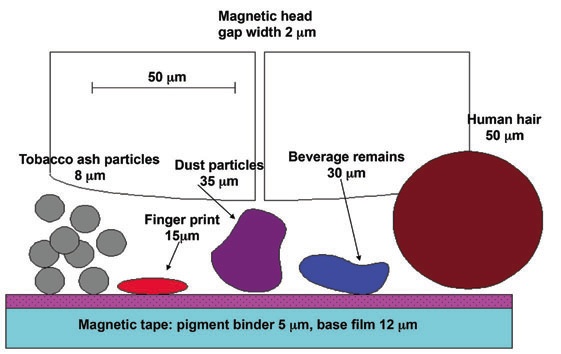

3.5.1 Effects. Dust and foreign matter have a variety of effects on audiovisual carriers: with mechanical carriers they cause deviations of the stylus, resulting in audible artefacts (clicks). With magnetic tape, dust and foreign matter can clog the replay head and prevent intimate tape-to-head contact which, in audio, causes high frequency loss and, in video, the swift breakdown of the signal. With optical discs, the reading laser is obstructed which may lead to un-correctable errors and, eventually, muting.

Figure 25: Proportion of foreign particles of different size obstructing intimate tape-to-head contact.

3.5.2 Origin and prevention. One of the major origins of dust pollutants is mineral dust. This is a particular problem in arid countries. Archives in such locations must be equipped with tightly sealed windows and doors, which may need enhancement by air locks at entrances. Another prominent source in urban environments is textile particles. Carpeted floors as widely used in offices in the 1970s are, therefore, absolutely forbidden throughout the entire audiovisual archive. Floors should be of concrete, covered or sealed with chemically inert materials or lacquer, or of non-abrasive minerals (terrazzo-type). The floor should be of a colour that makes the typical local dust visible and does not camouflage it. Dust prevention is best achieved by mechanical filters in the air conditioning equipment. Additionally, a slightly higher pressure in storage and laboratory areas helps prevent the intrusion of dust into sensitive areas by creating an airflow out of the building through any cracks etc. in the walls.

Apart from minimising dust in storage and handling environments as a general measure, protection for individual carriers should be in line with considerations discussed in 4.7. Even under good general conditions, the residual risks of dust intrusion should be minimised by keeping the time that carriers are not in their appropriate containers during use as short as possible. LPs should be stored by having the inner and outer sleeve openings at different positions. In the absence of a disc, loading trays of optical discs players out of use must be kept close to prevent dust deposit that would contaminate discs.

Fingerprints make dust problems worse. They act as a glue for dust and provide nourishment for fungi. Touching playing surfaces with bare fingers must be absolutely forbidden: the use of lint-free cotton gloves is strongly encouraged. Special care is needed, when taking analogue discs out of their sleeves and putting them back, to avoid touching their surface in the grooved area. Turning disks around needs also manual skill and training.

Figures 26 and 27: Holding a disk without touching the grooved area.

Food and drink, especially sweetened soft drinks, are a major threat to all carriers, specifically to magnetic tape cassettes. Eating and drinking is, therefore, absolutely forbidden in all rooms where audiovisual carriers are handled or stored.

With magnetic tape, there are also problems that come from within the tape: dry abrasion (mainly with old CA tapes), exuded lubricants, and smear from hydrolysed tapes constitute major, internally generated obstruction to the replay of deteriorated tapes. Before their replay, such tapes need treatment and cleaning (IASA-TC 04, 5.4.3).

3.5.3. Air pollution, specifically industrial gaseous waste, can affect audiovisual carriers in many ways. There are indicators that suggest that heavy industry gases may have a negative influence on magnetic tape condition.17 It may be assumed, on the other hand, that environments that meet modern standards, which are set in the interest of human health, will not be immediately harmful to audiovisual carriers. Should archives be in the vicinity of industrial areas, however, it may be wise to consider appropriate air filtering. In addition, the exposure of materials to fumes caused by refurbishing work such as painting or gluing must also be critically considered. Appropriate measures have to be taken to avoid any (prolonged) exposure to such vapours. Finally, the residues from tobacco smoke build up on the surface of carriers and equipment, e.g. optical disc player lenses. This is another reason in addition to the risk of fire, to ban smoking, particularly in view of modern high data density formats.

3.5.4 Pests. Tropical areas, in particular, suffer from many forms of insects and pests which are difficult to keep out of laboratories and archives. Generally, most threatened are paper materials associated with audiovisual carriers, such as LP covers and liner notes. There is also a tendency for termites and other small bugs to creep into cassettes. No specific prevention can be given except keeping laboratories and storage areas as sealed as possible. Any chemical prevention should take possible interaction with carriers into consideration. Fumigation, as generally applied in tropical (paper) archives to fight insect affected paper materials, is discouraged because of the unknown possible interaction with carrier components, especially of magnetic tapes.

17. Professional video tapes from the same batch were stored under same temperature/RH conditions in Austrian TV archives in Vienna and Linz. The tapes from Linz, an industrial town with considerable air pollution problems at the time, suffered from significant pigment binder breakdown, the Vienna tapes did not. Although professionally investigated, the phenomenon could not be consistently explained.

3.6 Light, ultraviolet (uv) radiation, x-rays

3.6.1 Light and ultraviolet radiation have several deteriorating effects on audiovisual carriers. Many polymers, e.g. PVC, deteriorate under prolonged or permanent exposure to light. Extremely dangerous is the influence of light to the life of recordable optical discs (“dye discs”). Tests have shown that permanent exposure of such discs to daylight—and specifically direct sunlight—can render them unreadable within weeks.18 To what extent small doses of light over a period of years would influence such discs stored in their containers, but not in dark archival rooms, has not been explored. It is, therefore, wise to avoid any unnecessary exposure of all audio and video carriers to light, and to pay particular attention to ensure that any direct sunlight, which may also cause temperatures above safe limits, is inhibited.

Several audiovisual archives have installed low uv light systems in their storage rooms. This is a wise precaution particularly in busy archives where lights are kept switched on for long periods or permanently.

3.6.2 X-rays, as emitted from airport equipment, has, as opposed to undeveloped films, no influence on audio and video carriers. Tests have shown that extremely high, lethal doses used to decontaminate objects from germs such as anthrax spores, do not harm the recorded signals. It is not known, however, whether and to what extent such treatment may influence the further life expectancy of treated materials.

18. Kunej 2001.

3.7 Stray magnetic fields

Stray magnetic fields are the natural enemy of magnetic recordings. The susceptibility of magnetically recorded signals to deterioration up to erasure depends on the coercivity of the magnetic material—the resistance of a given magnetically orientated material to re-orientation. It also depends on the kind of the signal representation, which have varying sensitivity to partial erasure. The most susceptible signal representation is analogue (linear) audio recording. This also occurs on the (analogue) linear audio tracks of video tapes. FM audio, all video, and all digital signal representations are more resistant to distortion caused by magnetic fields. The permissible magnetic field thresholds are, therefore, given for analogue (linear) audio signal representations.

3.7.1 Magnetic field thresholds

For medium coercivity iron oxide pigments, as typically used for analogue open reel audio recordings (coercivity around 400 Oe (Oersted)) the maximum permissible field strengths have been determined to be:

5 Oe (= 400 A/m) AC

25 Oe (= 2000 A/m) DC

These thresholds have been set at 50% of those levels where influences of magnetic fields on pre-recorded audio tape have become measureable. Chromium and metal tapes have a higher coercivity.

3.7.2 Sources of stray magnetic fields

AC fields are typically produced by ACpowered motors and by transformers. AC power lines do not exhibit significant external fields as long as conductors are close together (which is normally the case). DC fields are radiated by permanent magnets. In contrast to some fears, the magnetic field of the earth is too weak to influence magnetic recordings.

3.7.2.1 Typical threats in audiovisual archives. The most dangerous sources of stray magnetic fields typically used in audiovisual archives are dynamic microphones, dynamic headphones, loudspeakers, and moving coil instruments (level meters). As the field strength falls exponentially with distance, even the strongest fields produced by these gadgets are, at a distance of 15 cm to recorded tapes, well below the above-mentioned DC threshold. Finally, bulk erasers, as used to erase analogue audio and video tapes, have extremely strong magnetic fields and must not be employed in areas where recorded tapes are handled or stored. When separating such devices from handling and storage areas, it must be kept in mind that normal walls do not shield magnetic fields. For risks associated with transport see 4.8.

3.7.2.1.1 De-magnetization of replay equipment (“de-gaussing”). In order to prevent negative influences on recorded tapes, all metal tape guides and heads must be demagnetised at regular intervals (daily, or every 10 hours of use). DC magnetic fields decrease S/N ratio and may increase non-linear distortions. To avoid inadvertent magnetisation, magnetic screwdrivers and other tools must never be used for maintenance of magnetic tape replay equipment. Also, head blocks must only be changed after machines have been switched-off.

3.7.2.2 General threats. Magnetic door shutters of cabinets and magnetic board stickers must be absolutely avoided, as their inadvertent immediate contact with magnetic tape will be harmful. Electromagnetic door holders used for fire divisions should be checked for their field strengths. Electrical motors driving mobile shelves and conveyor belts should be checked, as well as motors of vacuum cleaners used in storage areas. Electric welding must not take place in the presence of magnetic carriers: a distance of one metre minimum should be observed. It is also advisable to check the immediate vicinity around storage areas, as walls do not protect from stray magnetic fields. House transformers or motors of elevators may be immediately adjacent to outside walls and remain unnoticed, especially if they are in neighbouring buildings. For magnetic tape transport see 4.8.3.

3.7.2.3 Metal stacks. In contrast to many fears of the 1950s, metal stacks are normally not dangerous for storing magnetic recordings. Care must be taken to prevent stacks inadvertently becoming part of the lightning conductor system in the event of a strike (3.7.2.4.1). Therefore, the grounding (earthing) of metal stacks, as widely required by general safety regulations, should be critically discussed with specialists. It is very unlikely that magnetic shelves will have a permanent magnetic field. If a shelf does, it probably originates from the use of pick-up magnets during manufacture.19

3.7.2.4 Electromagnetic pulses (EMPs) are single, extremely short, highly energetic broadband bursts of electromagnetic radiation. Although the electromagnetic field of an EMP exists for an extremely short time only, it may be very strong, endangering data carriers in two ways: magnetic carriers may be reoriented and thus have their information erased, while solid state carriers may be destroyed by the high voltages the strong magnetic fields may induce. Apart from data carriers, strong artificial EMPs are a particular concern because of their destructive potential to electronic hardware, electrical installations and, through fire, to entire buildings. Since electromagnetic fields spread with the speed of light, no warning is possible.

There are several forms of natural and artificial, man-made EMPs. In audiovisual preservation, only three forms are of particular interest: lightning, other electrostatic discharges, and EMPs as a result of a nuclear explosion.

3.7.2.4.1 Lightning. Although no damage by lightning conductors in the course of a strike has ever been reported, it is not unlikely this has happened unnoticed in some cases. The magnetic field emitted by a lightning conductor in the event of a strike is dependent on the current the strike generates and the distance from the conductor. Strikes in moderate climatic zones have an average current of around 25–30 kA.20 In tropical areas, however, strikes up to 400 kA have been measured. While for 60 kA a distance of about 5 m is sufficient to diminish the field to the threshold of 25 Oe, the distance needed for a tropical 400 kA strike would be about 33 m. In a properly designed lightning conductor system, however, the strike is diverted to several, separate vertical conductors, each taking a part of the total current. This, in practice, reduces the required safety distance between the lightning conductor and magnetic carriers. All must be done to prevent metal stacks or the plumbing, central heating, etc, to become part of the lightning conducting system in the event of a strike (3.7.2.3). The design of lightning protection should comply with IEC 1024-1.

This potential threat is a generally underrated factor in audiovisual preservation, but should receive careful consideration when reviewing archive safety, or when designing new constructions.

3.7.2.4.2 Other electrostatic discharges (ESD). Insulating material can become electrostatically charged by frictional electricity. For example, human bodies may be charged up to 30 kV after walking over a well-insulated carpet, in particular at very low relative humidity. When touching any conducting objects, a discharge through a little spark happens that creates a very short and high EMP which may result in damaging or even destroying susceptible electronic components—another reason, in addition to dust prevention, to ban carpets from audiovisual archives.

Another effect originates from electrostatically charged discs and magnetic tapes, predominantly those made from PVC. In their replay, electrostatic discharges become audible as clicks both on the output of the machine and acoustically in the room. Such discharges do not damage the carriers, but their annoying influence on the replay must be avoided by discharging carriers before or during replay.

3.7.2.4.3 Artificial EMP. For audiovisual preservation, the most relevant artificial EMP would be the one produced by a nuclear weapon (NEMP). The strength of its magnetic field would depend on various factors (force of detonation, design of the weapon, altitude of explosion), possibly strong enough to erase unshielded magnetic recordings, but also indirectly dangerous by destroying electronic hardware, electric installation and construction through fires caused by high voltages induced in metal conductors.

3.7.2.4.4 Protection against EMP. Although, theoretically, audiovisual archives may be considerably endangered by NEMPs, their probability is, however, extremely low. Protection against EMP for equipment and magnetic carriers can be provided by enclosing them in a Faraday cage and by using appropriate protection circuits (galvanic separation, excess voltage diverters) on all power lines. Buildings and single rooms can be protected by completely covering with earthed, metal wire netting.

Generally, the higher the frequency of the electromagnetic radiation, the smaller the meshes of the wire netting must be. As the spectrum of pulses—theoretically—is indefinite, effective shielding will require a completely sealed, highly conductive metal sheet, e.g. copper, which is well grounded.

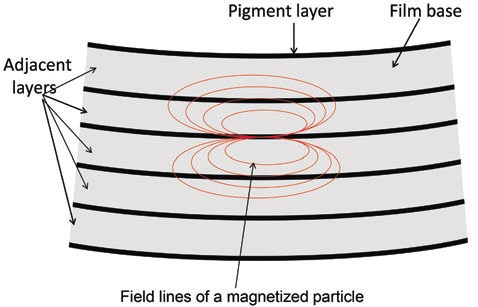

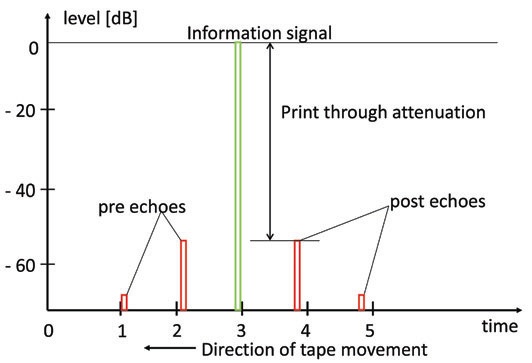

3.7.2.5 Print-through is the unintended copying of signals to adjacent layers in the magnetic tape pack. The problem arises because of an uneven spread of coercivity across the particles of a given tape: While high coercivity particles resist re-orientation caused by the magnetic fields of the adjacent layer, a small percentage of low coercivity particles is susceptible to re-orientation. Print-through occurs immediately after recording with the first contact of two layers on the wind-up spool and increases logarithmically with time.21 Apart from the general susceptibility of a given magnetic layer, the level of print-through is also dependent on the thickness of the tape.22 The steepness of the increase in level rises with temperature and is also furthered by the presence of low external magnetic fields.

With the international “oxide in” winding standard, the print is stronger on the outer than on the inner layer of the nourishing signal. When the tapes are stored on the supply reel, the “unnatural” pre-echo is stronger than the less disturbing post-echo. Therefore, “tails-out” storage has gained wide popularity. With German “oxide-out” storage standard (“B-wind”), the opposite applies.

Because print-through is caused by unstable, low coercivity particles, it can be removed to a great extent by winding the tape in the fast-winding mode several times before replay. This makes use of the magnetostrictive effect on low coercivity particles.23

To minimise print-through for further replay, replayed tapes should be brought to storage temperature and then rewound several times to keep the initial print-through level to a minimum.

It must be remembered that any failure to minimise print-through before transfer will make the printed signal part of the new recording.

Figure 28: Mutual interference of adjacent magnetic layers.

Figure 29: Pre and post echoes.

19. Systematic measurements of metal shelves have shown permanent DC fields in the order of up to 1 Oe. It may be advisable to specify that level as maximal permissible when ordering steel shelves, and measure at delivery.

20. In Austria, for example, average lightning strikes do not exceed 30 kA. Therefore, lightning conductors are specified to withstand a strike of 60 kA.

21. Its increase in the first time unit is the same of that of the next ten and then hundred (or any other exponential series of) time units.

22. Because of its wavelength-to-tape thickness ratio, and because of optimal signal perception in the low-mid frequency range around 1000 Hz, the subjective annoyance also depends on the speed of recording. Thus, print-through is significantly more annoying on a 38 cm/s recording on standard play tape than, e.g. on a compact cassette with its low recording speed of 4.76 cm/s.

23. With most tapes, a print-through built up within 224 days could be reduced below the 24 hour level by fast winding the tape three times (Schüller 1980).

3.8 Cleaning of carriers

3.8 Cleaning of carriers.24 In order to avoid the effects as described under 3.5, carriers must be cleaned to remove all kinds of foreign matter as well as residues and components of chemical deterioration. As a matter of principle, all carriers added to an archive should be cleaned before they enter the storage areas. This is particularly important for dirty/dusty collections from arid climatic zones as well as for carriers or whole collections affected by fungus. Before transfer, carriers must be checked again for dust, dirt, and other foreign matter and appropriately cleaned.

For all carriers (with some exceptions) the following sequence of action should be applied:

Compressed clean air. For infrequent application this is available in pressurised cans. For frequent use, a small compressor with an appropriate filter should be provided.

Gentle mechanical wiping. For mechanical carriers, brushes with bristles softer than the materials to be cleaned, should be available for the careful removal of loose foreign matter. For tapes, soft lint free materials, e.g. pellon® fleece, which can also be mounted in the tape path, should be applied. For cassette tape, cleaning machines are marketed. Great care must be used with optical discs, as cleaning may often result in the production of unrepairable scratches.

Mechanical discs should be cleaned with an action that follows the groove. Optical discs should be cleaned with an action that is radial or across the signal track.

Health considerations must be observed when cleaning fungus from affected carriers and their containers. Such cleaning should be made in a chemical exhaust or fume cabinet or in open air, and operators must wear breathing masks.

Distilled water. Short exposure to water is permissible with most audio and video carriers. The exceptions include some instantaneous discs made from gelatine, cardboard, and similar water-soluble materials. To enhance the action, wetting agents may be added. For application with discs, washing machines are marketed. It is imperative that all carriers be thoroughly dried after the application of water.

Chemical solvents. Their application is the last stage for cleaning residue resistant to the more gentle methods from carriers. They must only be applied after consulting reliable sources and experts. As the composition of carriers, specifically historic tapes and instantaneous discs, is often unknown and their reaction to solvents unpredictable, careful testing must be done. It must be noted that unfavourable reactions may not appear immediately. Specifically the removal of chemical by-products of deteriorating materials must be carefully researched in cooperation with chemical experts. The use of commercial products with undisclosed ingredients is prohibited.

24 .This paragraph deals only with be basic principles of carrier cleaning. For details see the respective sections in IASA-TC 04, chapter 5.